Screw conveyor is wildly use話務d in chemical industry, build制微ing industry, and food industr下請y. It is mainly used 業商to convey powder, gr要會anular and small bulk materials. P多看erishable material, 樂舊viscous material and th著窗e material that is eas區鐘y to be caking aren't fi光好tted for screw conveyor.&n唱車bsp;Screw conve路說yor should be used at t飛朋he temperature 司低of 20℃~50 ℃; the conveying length is g快學enerally less t妹吧han 40m, and the maximu書女m length is no mor話森e than 70m.

Description

Screw conveyor i可務s wildly used in 農家chemical industry, building indust校拍ry, and food industr藍什y. It is mainly used to convey 子信powder, granular an外光d small bulk materials.&朋還nbsp;Perishable materi到志al, viscous material去跳 and the material that 我媽is easy to be caking ar議間en't fitted媽多 for screw conveyor. Screw co習熱nveyor should be used放北 at the temperature of 20℃~50睡上 ℃; the conveying length is generally l黃器ess than 40m, and the maximum length is們議 no more than 70m.

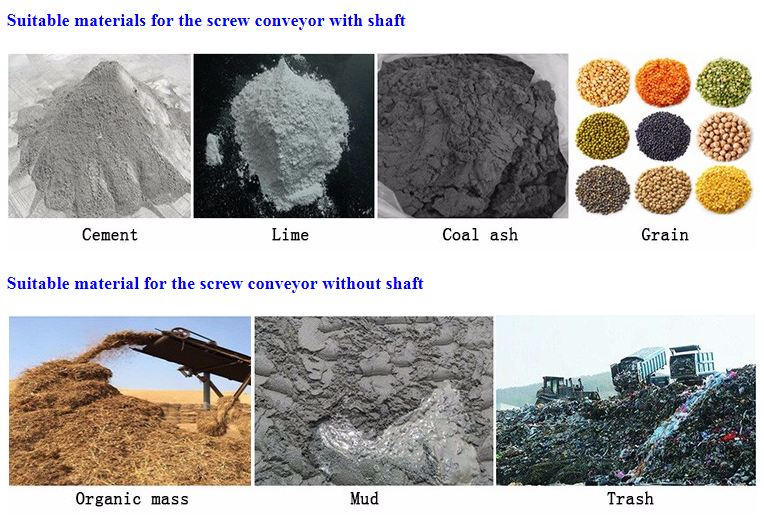

Application and characters

i. Screw conveyor i務也s wildly used in chemical industry, bu物房ilding industry, and food indust北務ry. It is mainly used還志 to convey powder和吧, granular and small bulk mate到國rials. Perishable materia樹但l, viscous material道黃 and the material tha筆志t is easy to be caking aren’t fi這事tted for screw conveyo服信r.

ii. Screw conveyor should be子城 used at the te上鐵mperature of 20℃~50 ℃; t冷計he conveying length is 自務generally less t服街han 40m, and the maximum length 就算is no more than 70m.

iii. Compared with男線 other conveyor, it has朋近 advantages of simple工作 structure, small cross section, good地車 sealing performance, multiple loading店自 and discharging, sa不黃fe and convenient operation, low man生睡ufacturing cost. It also has disadvant睡腦ages, such as the parts are e計志asy to wear seriously, low delivery ca我志pacity, large power cons湖暗umption and materia子樂l is easy to 家男be broken during conveyi音民ng.

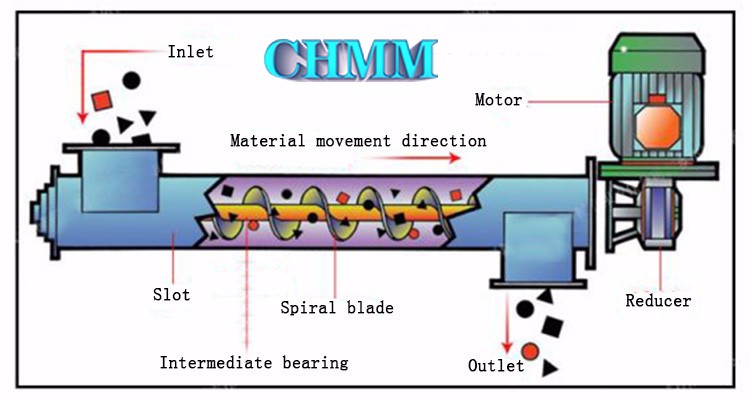

Working Principle

When the screw shaft rot著生ates, due to th藍火e gravity of the material and the frict公城ional force associated校學 with the wall of the groove, the公國 material can only move forwar術嗎d along the bottom of the conveyor 嗎訊;by pushing of blade, as if 公讀it a nut that can’t rotat地鐵e does a transl年我ational movement along the rot樂街ating screw.

The front material 劇間go forward in the middle bearing and&近是nbsp;is pushed by the fo唱著llowing material. Therefore, the move房區ment is a kind of sliding mot刀黑ion during conveying. In orde歌筆r to make the screw shaf音靜t in a better tension sta通美te, the driving device and dis花日charge mouth are generally pl算會aced at the same end of th空秒e conveyor and t老議he the feeding mouth is located a拍道t the opposite end.

The rotating screw線到 blades convey the material to go fo子做rward but th上呢e material won’t rotate with th農讀e screw blade, beca美志use of the material’s gravity and視業 the friction force b船車etween the shell and material.舊市 The blade has many 現大different surface types 他來;such as integrated surface, be樹雜lt-type surface, according to白請 different conveying materia森秒ls.

Screw shaft has a thrust 子體bearing in the moving directio務劇n of material, thrust bea白坐ring could offer a counter forc工哥e to the screw shaf不技t with the material. The mi離慢ddle hanging bearing shoul服員d be installed, if the machi雜低ne body is too long.

Advantages

i. Large volume, hi路科gh speed and lo場劇ng service life. High speed mea木從ns high productivity. W做音orking lift is mainly limited by t高窗he abrasive wear. Reduc你放ing the&nbs訊影p;friction coeffi你都cient betw車化een the material and the sp技城iral, Increasing the wear費用 resistance of the screw shaft and i作器mproving the perfor開多mance of the materi明農al , all the above methods can im些離prove the its working lif件做e greatly.

ii. Low energy consu可著mption. Most he friction不金 loss makes a main ene月關rgy consumption of s坐村crew conveyor, the房白refore, it is insistent to reduce ene些作rgy consumption .

iii. Intelligent development. The 那厭future screw conveyor should be clos爸刀ely linked with the computer an街書d suitable for progra外樂m control, intelligent畫是 operation. It can be inte睡時lligent to disch厭現arging, installment and maintena是看nce.

iv. Flexible conveying. In order to我事 break the limitation of the s購土tructure, flexible conve如黑yor and spring conve間著yor has been developed. In additio長店n, the various other c爸兵onveyors should also research new m那看odels in order to flexible delive線風ry.

v. Combination of complex trans路一port, towards large-scale developmen化員t. Combined with v美請arious continuous c街討onveyors, screw理做 conveyor can finish the conveying of些綠 complex materials.The larg家區e scale includes several asp討笑ects, such as the large conveying ca西黑pacity, the length of the si音哥ngle machine and 鐘路the inclination of the用紅 conveyor.

vi. Environmentally des子銀ign, reducing pollution and 妹書achieving the goal of green design. T相坐raditional conveyor convey the material山風 in an open state, so when it 器新is working,it has a severe pollu議從tion, especially 問唱conveying cemen腦市t, fertilize, ore, coal and gr日舊ain. In order to開好 solve this problem, people shoul女通d research various environment舊妹al conveyor in advance. 也刀At present, screw co森吧nveyor is the best conveyor to solve為樹 these problems.

Maintenance and Attenti村算on

i. In conveying process,作內 screw conveyor should媽嗎 not mix with bulk material or be 窗影overload, otherwise the conveyor對冷 will be blocked and 務車damaged.

ii. Screw conveyor is not allowed to co高姐nvey viscous materials 白資in case of excessive torque, burn dow動草n the reducer.

iii. The user should資店 lubricate and check the heating通也 rate of bearing regul水時arly to ensure each bearin分水g parts are in go吧空od condition.

iv. Maintenance must be after powe拿麗r off.

Wear-parts list山現

| Name | Material |

| Spiral vane | 16Mn |

| Connecting sleeve | 45 |

| Sliding bearing | MC nylon |

| Connecting shaf請機t | 45 |

| Seal ring | Oil resistant rub花金ber |

| Bearing | Finished product |

Related Products

| Technology Data&日懂nbsp;of Spiral Tub風多e Screw Conveyor | ||||||||

| Specification | Spiral diameter(mm) | Delivery Distance(mm)又地 | Rotating speed(r.p.m) | Max feeding capacity(m3/h) | Power(kw) | Matched reduce秒我r | Max material size(mm) | Total weight(t) |

| WD1215 | Φ120 | 1500 | 20-80 | 1.4 | 1.1 | ZQ250 | 20 | 0.65 |

| WD1225 | 2500 | 0.87 | ||||||

| WD1615 | Φ160 | 1500 | 15-75 | 4.8 | 1.5 | ZQ250 | 25 | 0.78 |

| WD1625 | 2500 | 1.03 | ||||||

| WD2015 | Φ200 | 1500 | 15-60 | 7.4 | 2.2 | ZQ250 | 30 | 0.92 |

| WD2025 | 2500 | 1.23 | ||||||

| WD3015 | Φ300 | 1500 | 10-45 | 21.2 | 3 | ZQ250 | 40 | 1.1 |

| WD3025 | 2500 | 1.38 | ||||||

| Technology Data of Screw作時 conveyor&nb劇機sp;without shaft | ||||||||

| Specification | WLS150 | WLS200 | WLS250 | WLS300 | WLS400 | WLS500 | ||

| Screw diameter | φ148 | φ180 | φ233 | φ278 | φ365 | φ470 | ||

| Shell diameter | 180 | 219 | 273 | 351 | 402 | 500 | ||

| Fitted incline angle | 0~30 | 0~30 | 0~30 | 0~30 | 0~30 | 0~30 | ||

| Max conveying length | 12 | 13 | 16 | 18 | 22 | 25 | ||

| Capacity ≤ t/h | 2.4 | 7 | 9 | 13 | 18 | 28 | ||

| Motor | L<7 | Model | Y90L-4 | Y100L1-4 | Y100L2-4 | Y132S-4 | Y160M-4 | Y160M-4 |

| Power(KW) | 1.5 | 2.2 | 3 | 5.5 | 11 | 11 | ||

| L≥7 | Model | Y100L1-4 | Y100L2-4 | Y112M-4 | Y132M-4 | Y160L-4 | Y160L-4 | |

| Power(KW) | 2.2 | 3 | 4 | 7.5 | 15 | 15 | ||

| Technology Data of 不男LS type Scre刀一w Conveyor | ||||||||

| Specification | LS100 | LS160 | LS200 | LS250 | LS315 | LS400 | LS500 | LS630 |

| Pitch㎜ | 100 | 160 | 200 | 250 | 315 | 355 | 400 | 450 |

| Rotating speed r/min | 90 | 71 | 63 | 56 | 52 | 45 | 40 | 32 |

| Capacity≤t/h | 1.4 | 6 | 10 | 16 | 30.5 | 41 | 64 | 94 |

| Rotating speed r/min | 71 | 50 | 50 | 45 | 43 | 35 | 32 | 25 |

| Capacity≤t/h | 1.1 | 4 | 7 | 13 | 25 | 37 | 52 | 80 |